Managing materials is always one of the most difficult areas for a plumbing or electrical business to get a handle on.

Your tradespeople are moving materials from van to van, unused stock is lying around waiting to be returned, and there’s always the odd item that goes missing. Costs can quickly escalate, eating up your profit margin.

The good news is it’s not hard to keep stock control in check. Like every administrative function in a well-run trades business, all you need are the right systems and processes in place to make sure stock is accurately accounted for.

There are two very different ways of controlling your stock.

I’ve mentioned Just in Time Stock Control before. It basically boils down to buy what you need, when you need it – a great way to control costs and ensure there’s no waste.

But of course, it’s not a one-size fits all solution for all trade businesses.

If you live an hour or more away from your nearest supplier, it’s essential to hold stock.

If this is you, then start by following this first rule of thumb:

Nothing should enter or leave your warehouse or stockroom without being charged to a specific customer.

This sounds fairly simple, but material handling can be quite chaotic, especially if you don’t have plumbing and electrical software to help you with forecasting. You may have a warehouse full of supplies, but your team will still pick up materials from your local supplier, and you’ll also get the occasional delivery.

It can get out of hand really fast.

To manage stock effectively, consider setting up a warehouse to have two points of entry – one for staff and one for deliveries of large items.

After you have set your warehouse up (including somewhere for suppliers to drop all inwards goods for processing) – consider creating an outwards goods counter with a narrow exit behind it.

This will remind people that stock should not be removed until it has been processed.

It’s essential that NOTHING leaves your warehouse without being charged to a specific customer.

Ideally, you should have a couple of computers set up on the counter in your warehouse – one for inwards goods and one for outwards goods and credits.

It’s a good idea to make sure that the computer screens are always on – you will want to encourage your team to enter in the details at every step of the way.

Don’t let the “I’ll do it later” mentality seep into your business culture.

Again, keep it simple – so there is no room for excuses. You don’t want staff putting materials back into the stock racks until it has been processed into your stock control system.

Another suggestion, once you are able to afford it – of course, is that you put someone in charge of the warehouse during work hours to record stock movement.

We hired a local high school student who came in after school in my last plumbing business.

The student processed the credits and inward goods, as well as doing other odd jobs.

A few more handy tips regarding stock control:

Just remember, with the system outlined above, the materials will have been charged to a job so don’t worry too much if your Tradies are swapping materials between vans.

You’ll also find, once you’ve got a good system in place that makes it easy for your tradies to return unused materials, the amount of excess stock lying around in vans starts to drop.

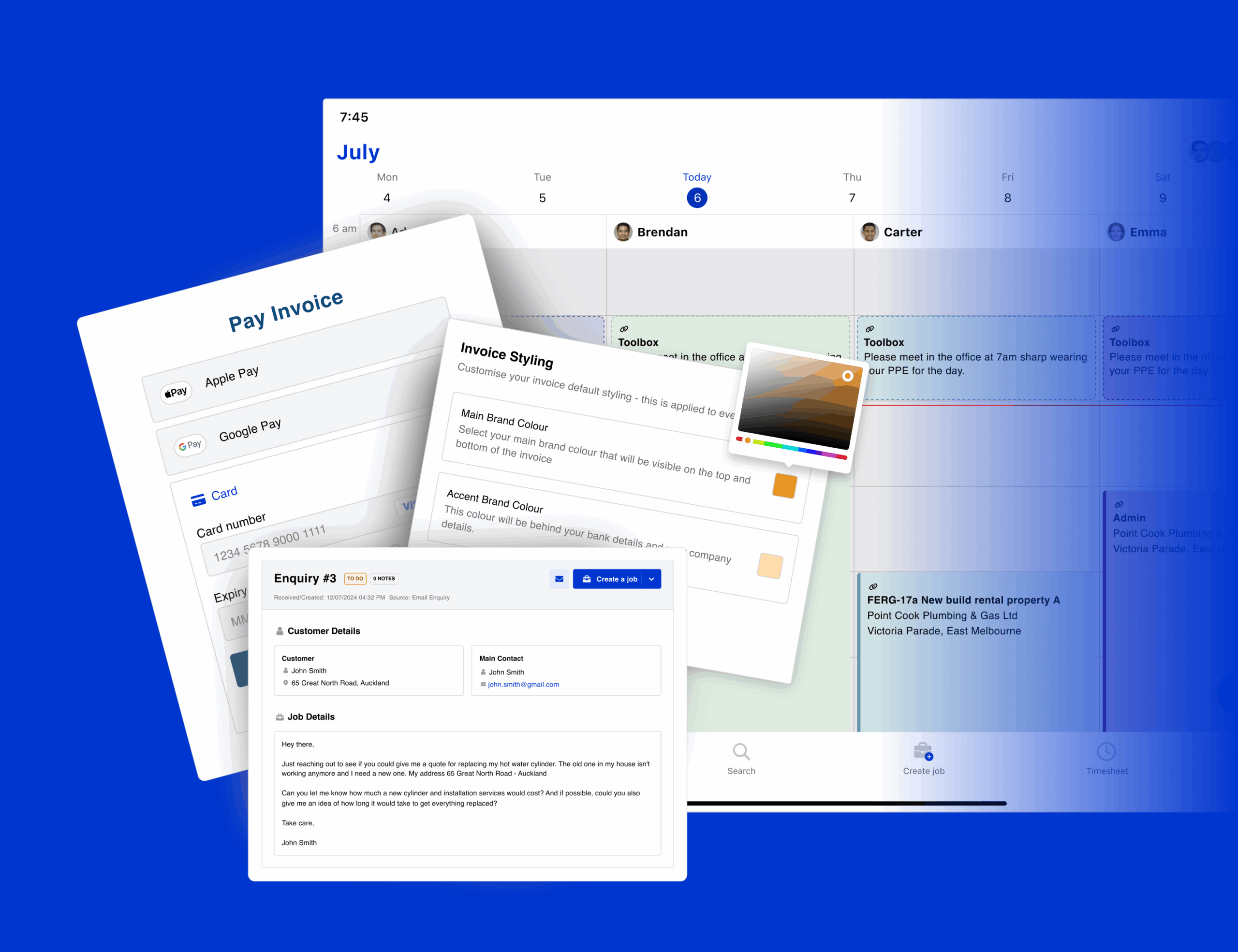

Stop drowning in admin & paperwork. Start focusing on the jobs that make you money.

Our 20,000+ trades businesses have slashed their admin, are getting paid faster, and are finally enjoying their weekends again.

Chat with a Fergus expert to see how we can cut your admin time, keep your jobs on track, and get you paid faster.