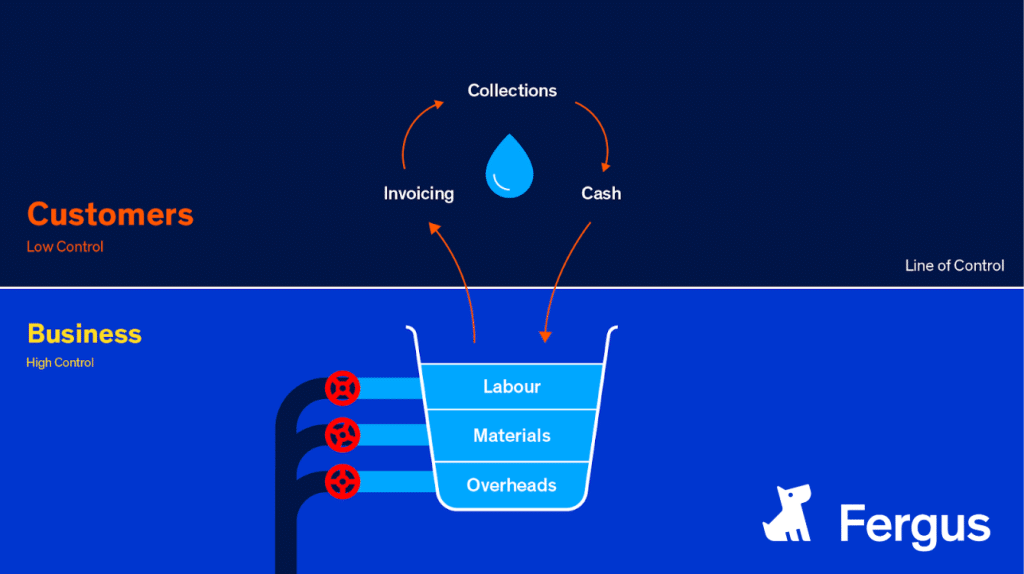

Think of your business as a bucket with holes in it. Money earned from jobs fills the bucket up, while various running costs create holes that let your hard-earned profit escape. Some costs are necessary evils that go hand-in-hand with owning your own business, while others are completely controllable and can be ‘plugged’ with good management. One of the ‘holes’ is materials.

As I see it, you will never have a profitable, sustainable or easy-to-grow trades business until you learn to control materials. When I talk about a business having materials under control, I mean a business that knows every piece of material bought is charged to a job.

Sounds easy, but it’s far from it. Controlling materials is a vast and wide problem that affects many business owners. Why? Simply put, there are many fingers touching the supply chain and each of these people adds a layer of complexity and confusion, reducing clarity and responsibility.

In order to get materials under control there’s one simple change you have to make, then stick to it come hell or high water and never relinquish the will to control the outcome of that decision.

So, what’s the one policy decision you have to make? Simple: Materials are bought for each individual job, every single item is charged to that job and nothing is ever bought for stock (with the exception of generic consumables like screws and glue etc).

Make this change and you’ll solve a number of problems, including:

Yes, it’s a policy that’s probably going to cause arguments and dissension amongst you, but I’ve fought this fight so many times and never won so bring your best fight!

Before you launch, let me explain my logic… A classic mistake we’ve all made (some still are) is buying what’s convenient, not what you need. For example, you’re a sparky working on a new house. You need 23 power points for the job, and that’s what you quoted. But when you went to the merchant you bought 3 boxes instead. So now you have 30. At the end of the job there are 7 left over. In your ideal world, you plan to use them on another job – at least that’s what you tell yourself will happen. In reality, they get left in the garage and forgotten about, they get damaged, or maybe one of the guys does a cashy for a mate and grabs them from the van.

Long story short, they never get charged to another job and you lose money. They’re only small items but because the profit margin on them is so low, you’ve managed to turn what could have been a profit line item into a loss leader – and none of this would have happened if you’d only bought the 23 you actually needed in the first place. Multiply this by the number of jobs you do each year and all those small losses start to add up…

So how does this look on a day-to-day basis:

Is this actually possible? Absolutely. Is it difficult to do? Absolutely. But is it worth the effort? Put it this way: there’s no other option if you want to grow a business and not go bankrupt.

Stop drowning in admin & paperwork. Start focusing on the jobs that make you money.

Our 20,000+ trades businesses have slashed their admin, are getting paid faster, and are finally enjoying their weekends again.